Manufacture Facility

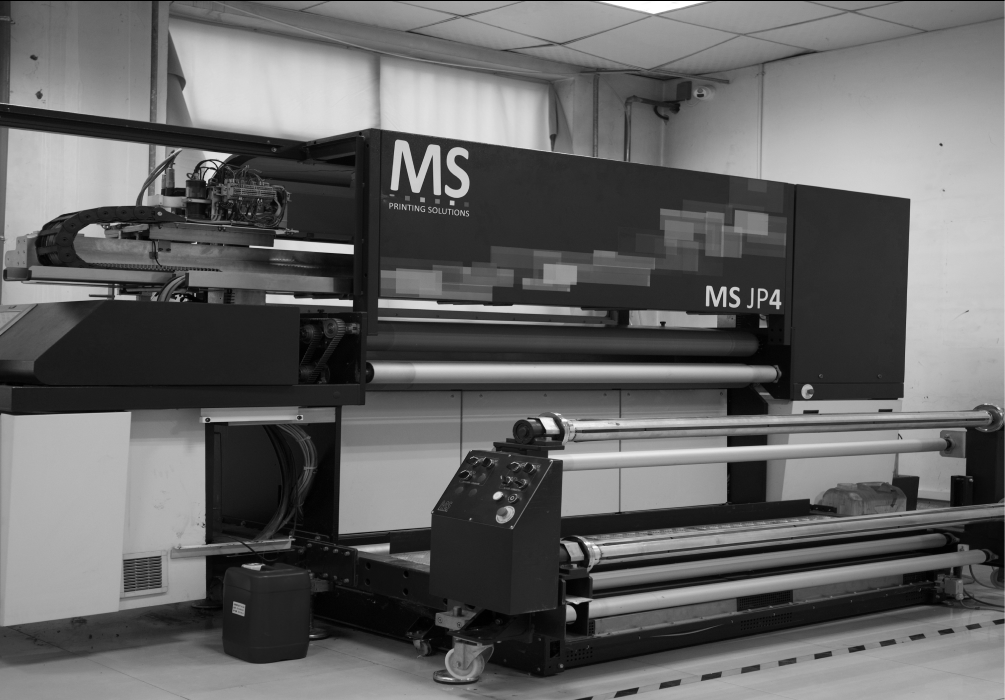

Digital Printing Machine

Atexco

Digital Inkjet Printing Machine

Printing Solutions

Digital Inkjet Printing Machine

Enhanced Print Quality

Higher Space Utilization

Breakthrough Performance

Products

Compact and functional, the machine can optimize the space and resources occupied in the manufacturing process, thus freeing up capital for new investments and helping companies to create more profits.

Equipped with 8 printheads, it creates a higher density of ink droplets in the image area with the same number of passes for top-notch high-speed printing performance.

The vacuum adsorption platform maintains optimal media fit and stability during the printing process, ensuring high quality output. The paper compensation lever in conjunction with the laser sensor enables perfectly synchronized movement of the paper at the highest speed allowed by the machine.

1. Green certification:"It is our duty to promote sustainable technology. We join the ACIMIT (Italian Spinning Machinery Association) initiative to improve the resource efficiency of textile machinery. Members are committed to operating in compliance, being Green Label Green Label certified, and using the appropriate logos on equipment that meets the standards."

2. Printing exhaust gas recovery systems:The plant adopts catalytic combustion and activated carbon adsorption to treat VOC (Volatile Organic Compounds) with an overall efficiency of 95%, and ensures that the emissions are better than the standard through real-time monitoring connected with the environmental protection department.

Top Print Quality

Optimization of Production Capacity

Streamlining the Process

Flexibility to Take Orders in Small Quantities

Rapid Delivery

Products

In order to meet the increasingly diversified demands of the middle and high-end markets, the company introduced the advanced Atexco digital printing equipment in China. The digital printing process can realize high-end effects on textile fabrics, shorten the traditional process route, and increase the speed of order taking. Digital production really realizes small batch, quick response, and is not limited by batch size, providing customers with higher quality products and more efficient service.

Printing exhaust gas recovery system:The plant uses catalytic combustion and activated carbon adsorption to treat VOC (volatile organic compounds) (efficiency 95%), and ensures that emissions are better than the standard through real-time monitoring networked with the environmental protection department.

Laminating Machine

Laminator "A"

Laminator "B"

Environmentally Friendly and Solvent-Free

Tension-Free Lamination

Automatic Operation

Low-Noise Equipment Operation

Maximize the Safety of Personnel

Products

Product Advantage: They adopt advanced coating technology, which can realize uniform coating under precise temperature control, and react with the substrate to form a super-strong adhesive bond with excellent resistance to high temperature and hydrolysis. With high degree of automation and fast laminating speed, the whole machine is suitable for many fields such as textile, automobile interior, filtration materials, etc. It is an ideal choice for improving product quality and production efficiency.

1. Hot-melt adhesive:Solvent-free hot melt adhesives are used to realize clean production and energy saving. The waterless formula does not require drying and relies on irreversible moisture curing to achieve fast bonding and excellent washing fastness. Equipped with a dedicated melting system for efficient adhesive production; combined with a precise spot gluing program for better lamination results.

2. Membrane-coated exhaust gas catalytic combustion equipment:Daroog adopts catalytic oxidation technology to convert VOC into CO₂ and H₂O at lower temperatures (200-400°C), which is characterized by low ignition temperatures, no open flames and high safety. The system is networked with the environmental protection department for real-time monitoring to ensure that emissions are better than industry standards.

Environmentally Friendly and Solvent-Free

high productivity

Products

Advantage: Adopting advanced coating technology, it can realize uniform coating under precise temperature control, and react with the substrate to form a super-strong adhesive bond with excellent resistance to high temperature and hydrolysis. With high degree of automation and fast compounding speed, the whole machine is suitable for textile, automobile interior, filtration materials and other fields, which is the ideal choice for improving product quality and production efficiency.

1. Hot-melt adhesive:Solvent-free hot melt adhesives are used to realize clean production and energy saving. The waterless formula does not require drying and relies on irreversible moisture curing to achieve fast bonding and excellent washing fastness. Equipped with a dedicated melting system for efficient adhesive production; combined with a precise spot gluing program for better lamination results.

2. Membrane-coated exhaust gas catalytic combustion equipment:Daroog adopts catalytic oxidation technology to convert VOC into CO₂ and H₂O at lower temperatures (200-400°C), which is characterized by low ignition temperatures, no open flames and high safety. The system is networked with the environmental protection department for real-time monitoring to ensure that emissions are better than industry standards.

Dyeing Machine

Wrinkled and Tinged

Roll Up (Hair)

Warp Beam Color Dyeing

Low tension operation to keep fabric soft

Natural crinkle texture gives the finished product a casual style

Rope loop process for three-dimensional wrinkle-dyeing needs

Products

Crepe dyeing (KSPD) belongs to the traditional rope dyeing process. Fabrics are circulated in the dyeing vat in a free and relaxed state, forming natural folds through mechanical action; the whole process has low tension, which can well maintain the soft handfeel of the fabrics. Due to the rope treatment, the dyed fabrics show unique wrinkle texture, which brings a natural and casual style to the finished products.

Energy-saving high-temperature fast automatic dyeing machine:Low pressure and high flow rate, even dyeing, shorten the dyeing time effectively. The special inner net structure of the cylinder can reduce the water consumption. Compared with the traditional dyeing machine, the energy consumption is reduced by about 20%.

Flat width dyeing, fabrics are flat and wrinkle-free

Precise tension control for woven fabrics

Low bath ratio process, energy saving and consumption reduction

Products

Coil dyeing is a flat dyeing process in which the fabric is coiled back and forth between two guide rollers in the dyeing liquid, and uniform dyeing is realized by running in forward and reverse directions. Its biggest advantage is to keep the fabric flat and wrinkle-free, and can precisely control the tension, especially suitable for cotton and polyester-cotton and other medium-thick woven fabrics. The process has a relatively low bath ratio and significant energy saving and emission reduction.

High-Pressure Osmosis Technology, Low Bath Ratio and High Efficiency Dyeing

No Mechanical Friction, Avoiding Creases and Scratches, Protecting High-Density Fabrics.

Green, Low Water and Energy Consumption

Products

Warp beam dyeing adopts high-pressure penetration technology, the fabrics are tightly wound on the porous warp beam in a flat state, and the dyeing liquid penetrates through the fabric layer under pressure to realize uniform coloring. Its core features are low bath ratio, low water consumption and low energy consumption, which meet the requirements of environmental protection. As there is no mechanical friction in the whole process, it can effectively avoid crease and abrasion, especially suitable for high-density fabrics, which is one of the mainstream technologies of green dyeing and finishing at present.

Testing Center

Testing Center

Color Fastness

Climate Simulation

Special Performance Tests

Testing Center

Labs

The testing center of the fabric dyeing and finishing factory is the core department of quality control, equipped with constant temperature and humidity experimental environment (temperature 23 ± 1 ℃, humidity 65 ± 2%) and advanced testing equipments (such as spectrophotometer, color fastness to rubbing meter, pH intelligent analysis system, etc.), to ensure the accuracy and stability of the testing conditions. Strictly following the international standards such as AATCC and ISO, the testing items cover color fastness, shrinkage, grammage and other key indicators. Through high-precision instruments and digital management system to achieve data traceability, to optimize the dyeing and finishing process to provide a scientific basis, to ensure that the fabrics meet customer requirements in terms of color consistency, physical properties and environmental compliance, to help enterprises to enhance the competitiveness of their products.

Color Fastness

Test (machinery etc)

Color fastness testing is used to evaluate the ability of fabrics to retain color under conditions such as rubbing, washing, and light. Standard instruments such as rubbing color fastness meter and washing color fastness machine are used to conduct the test according to international methods such as ISO and AATCC to ensure accurate data. The results are divided into 1-5 grades, with higher grades indicating better color fastness, providing a key basis for product quality judgment.

Situation

Analog (device, as opposed digital)

Climate simulation related tests simulate rain, air/moisture permeability, sunlight and other environments through specialized equipment to evaluate the performance of fabrics under extreme climatic conditions. We use equipment such as UV aging chambers, rain drenching testers, air permeability/permeability testers, etc. to test the weather resistance, waterproofing and air permeability of fabrics to ensure that the products remain stable and comfortable in real environments.

Specialty

Performance Testing

The Functionality Testing Laboratory focuses on the accurate verification of fabrics' special performance, covering key indicators such as yellowing, anti-drilling, anti-static and Martindale abrasion resistance. Relying on the electronic fabric strength machine and other precision equipment, the laboratory executes a testing process that is stricter than the industry standard, and provides quality endorsement for the R&D of high-end fabrics with millimeter-level precision data.

R&D Process

The process comprehensively covers all phases of fabric development and management, from sample order development to color card production, ensuring compliance with design and quality requirements at every step from analysis to manufacturing. (Self-refined)

- Organize the contents of the sample sheet to be developed, analyze the yarn, density, composition, and grammage according to the sample fabric, and check the finished product information to find the corresponding products.

- Finding a sample quotation from a blank factory, and making a sample order for blank fabric (confirming the cost/delivery time/quantity).

- A meeting is held to confirm that the specimen meets the requirements.

- Confirmation of the range of suitable uses.

- Sample colors are selected and released according to the use of the fabric.

- The designer selects a standard color based on whether or not the color sample is OK, and notifies the development assistant.

- Place your order according to the color details you have selected.

- Pay attention to production process requirements and product requirements.

- Sample personnel make color cards or hang cards according to the color/process of incoming samples.

Taroko is looking forward to

Work with you